Laying tiles on floors with underfloor heating

Civil work

Edification

SolutionLaying tiles on floors with underfloor heating

System description

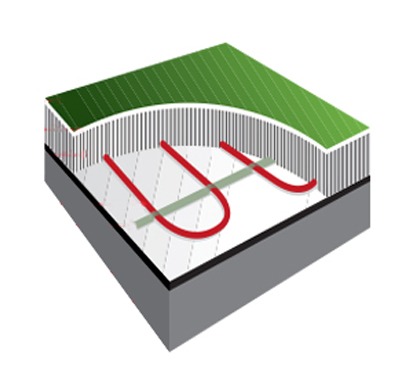

An increasing number of homes are being installed with radiant floor heating, due to the advantages it offers, including significant energy savings and comfort compared to traditional heating. There are two types, water underfloor heating and electric underfloor heating.

Radiant water tube heating, the most common.The water circulates at a maximum T of 45º C and the temperature on the surface of the floor is 18-22º C. Nowadays, radiant floors are even made with less than 3 cm, which is why they are installed in both new buildings and renovations.

A – Stoneware

B – Cement glue

C – NIVELANTE 80 mortar covering the pipe (min. 30 mm)

D – Pipeline

E – Isolation

Electric radiant heating by wire or heating cable. This system uses electrical energy to heat a stainless steel cable.The final thickness of the flooring is low, so it is commonly used in renovation.

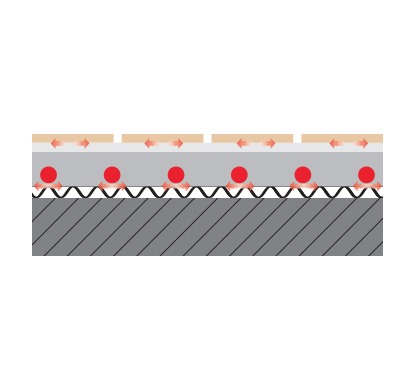

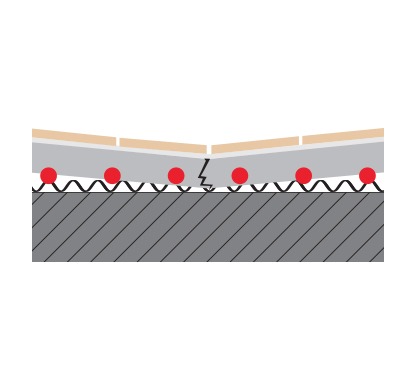

When the system is put into operation, the lower part of the mortar screed (next to the water pipes, temp. approx. 45°C) has a higher expansion than the upper part (surface temp. approx. 22-25°C).

This generates shear stresses in the ceramic tiles that can cause them to detach.

For a correct installation that guarantees optimum adhesion, it is necessary to use adhesive mortars that are highly flexible and easy to apply, such asPAM® ECOGEL FLEX,PAM® ECOGEL PORCEL, PAM® ECOGEL SUPERFLEX, VAT® PORCELÁNICO FLEX,VAT® FLEXIBLE, VAT® SUPERFLEX orVAT® FLEX RAPID.

Linked solutions

- INSTALLATION OF LARGE-FORMAT CERAMIC TILES ON FLOORS

- LAYING OF CERAMIC TILES ON OUTDOOR TERRACE

- LAYING CERAMIC TILES ON LARGE-FORMAT BRICKS

- CERAMIC TILE INSTALLATION ON FRESH MORTAR

- LAYING TILES ON PREFABRICATED GYPSUM BLOCKS

- LAYING OF CERAMIC TILES ON FAÇADES

- CERAMIC TILE INSTALLATION ON IRREGULARLY SHAPED SUBSTRATES

- LAYING CERAMIC TILES IN SWIMMING POOLS

- CERAMIC TILE INSTALLATION ON PLASTERBOARD SUBSTRATES

- LAYING OF PORCELAIN STONEWARE

- INSTALLATION OF NATURAL OR ARTIFICIAL STONE ON FAÇADES

- LAYING A TILING ON TOP OF AN OLD ONE

- LAYING CERAMIC FLOORING ON TOP OF AN OLD ONE

Related products

Solution: Laying tiles on radiant heated floors

PREPARATION OF THE SUBSTRATE

The mortar substrate must be strong, perfectly set and free of dust.

Check flatness with a 2 metre ruler; differences should be less than 5 mm.

The tiles should be laid when the mortar is completely dry or with a moisture content of no more than 2.5%.

APPLICATION

Knead with a slow electric mixer (500 rpm), spread and apply to the substrate using a notched trowel.

Press the tiles to achieve the correct bonding of all the pieces, thus avoiding the existence of gaps between the tile and the substrate. Double gluing is recommended in order to favour this circumstance.

Leave a minimum joint width of 2 mm and grout after 24 hours with the BORADA® range of joint mortars by Molins.

Recommendations

- Do not apply at temperatures < 5º C or >30º C.

- Expansion joints must be provided in door openings, for areas >40 m² or when the length is more than 2 times the width.

- The mortar substrate must be cleaned of dust and dirt prior to laying the tiles.

- In case of anhydrite levelling agent, use PROPAM GRIP + as a primer and bonding agent when dry and dust-free.

- The tiles must not be laid until 48 hours after the application ofNIVELANTE 80.

- It is advisable not to operate the heating until at least 7 days after application of the seal.

- It is always necessary to double glue the pieces, except when the adhesive used isPAM® ECOGEL FLEX or PAM ECOGEL SUPERFLEX in fluid consistency.

- Wrapping the water pipes or the heating cable, a layer of at least 30-40 mm ofNIVELANTE 80 must be laid on top of them.

Would you like to receive more information?

Complete this form and we will get back to you as soon as possible 🙂

España

España  Croacia

Croacia  Turquía

Turquía  Argentina

Argentina  México

México  Colombia

Colombia  Uruguay

Uruguay  Bolivia

Bolivia  Bangladesh

Bangladesh  Túnez

Túnez