Thermally insulating a façade with the PROPAM TERM 50 system with mineral finish

Civil work

Edification

SolutionThermally insulating a façade with the PROPAM TERM 50 system with mineral finish

System description

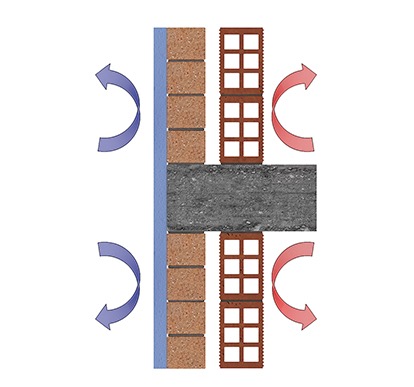

The use of lightweight thermo-insulating mortar for the creation of an Exterior Thermal Insulation System is a highly innovative and proven alternative to the expanded polystyrene (EPS) or rock wool (MW) board system. This type of product is a very good insulator and stable support when a traditional lime mortar finish is required, hence a mineral finish.

New façades must comply with the energy constraints imposed by the current Technical Building Code (CTE).

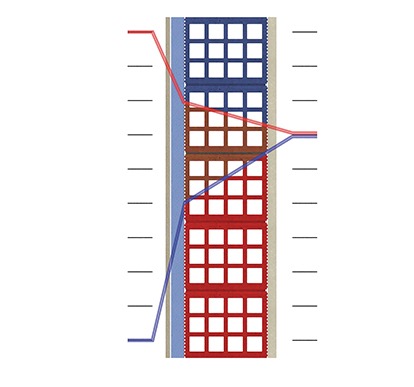

The high insulation capacity of PROPAM® TERM 50 mortar, with a thermal conductivity = 0.05 W/m.K, reduces energy consumption and improves the comfort and well-being of the home user.

The TERM 50 SYSTEM eliminates thermal bridges and the risk of condensation inside the home, thanks to its high vapour permeability, with a water vapour diffusion resistance factor μ ≤15.

PROPAM TERM 50: Continuous application, allowing for thicknesses of between 20 and 80 mm, it adapts perfectly to any facade geometry, providing solid, non-discontinuous thermal insulation, with different finishes and excellent mechanical resistance to impact and puncturing.

It enables construction costs to be reduced.

Linked solutions

- THERMALLY INSULATING A FACADE FROM THE OUTSIDE

- PROPAM TERM 50 SYSTEM INSTALLATION AND FINISHING GUIDE

Related products

Solution

PREPARATION OF THE SUBSTRATE

The substrate must be stable, free of dust, paint, oil, etc. Do not apply on plaster residues.

APPLICATION

Prepare the substrate using the appropriate rulers to define the total thickness of the Thermal Insulation System (thicknesses of PROPAM® TERM 50 + REVAT® CAL TRADICIONAL) and the size of the surface to be applied.

Apply PROPAM® TERM 50 by mechanical spraying.It can also be applied with a trowel in areas where it is difficult to use the spraying machine.Consumption is about 3 Kg/m2 and cm of thickness.

Use a ruler to achieve a flat and stable surface.

When the application thickness is between 40 and 80 mm, apply PROPAM® TERM 50 in two coats of approximately the same thickness. The second coat should be applied after the first coat has dried (1 day per cm of thickness). The second of these layers should incorporate a REVAT® MALLA FIBRA de VIDRIO 110 fibreglass mesh, which should be embedded in the surface of the fresh PROPAM® TERM 50 mortar with the help of a trowel and should not be visible.

Once the second coat is dry, PROPAM® TACO DE FIJACIÓN is installed (the type depends on the substrate) at a rate of one per m2.

For finishing coatings, wait for PROPAM® TERM 50to dry (1 day per cm thickness).

Then apply PROPAM® GRIP+ consolidation, adhesion and moisture regulating resin.

Finally, apply the REVAT® CAL TRADITIONAL finish coating, taking into account the reinforcement with REVAT® MALLA FIBRA de VIDRIO 110 glass fibre mesh centred on the thickness around door and window openings, as well as at singular points.

Recommendations

- It must be applied between 5º C and 35º C. In hot weather or dry wind, the substrate should be dampened with water.

- For the application of SISTEMA TERM 50 with organic or ceramic finishes, please refer to the “SISTEMA PROPAM TERM 50 Finishes and Installation Guide”.

Spain

Spain  Croatia

Croatia  Turkey

Turkey  Portugal

Portugal  Bosnia

Bosnia  Argentina

Argentina  Mexico

Mexico  Colombia

Colombia  Uruguay

Uruguay  Bolivia

Bolivia  Bangladesh

Bangladesh  Tunisia

Tunisia